Pioneering the alliance - a new challenge of the Three

NMKV was established in June 2011 as a joint venture, the first of its kind in Japan, which aimed to focus on the product planning/development management of Kei-cars for Nissan Motor and Mitsubishi Motors. Upon the requests/demands from two companies, NMKV responded to rearrange them for the purpose of product planning/development management, while Mitsubishi assumed the role of production and development of vehicles whose designs were determined by Nissan and Mitsubishi, respectively. In specific, the development process that included mechanical designing and performance testing was to be carried out at Mitsubishi Motors Technical Center (Okazaki City, Aichi) followed by the vehicle production at Mizushima Plant (Kurashiki City, Okayama). The height (tall) wagons released in June 2013 and the super height wagons released in February 2014 under the brand names of both companies were the first-generation Kei-cars born as the outcome of revolutionary NMKV collaboration.

DAYZ, Nissan Motor (Released in June 2013)

eK WAGON, Mitsubishi Motors (Released in June 2013)

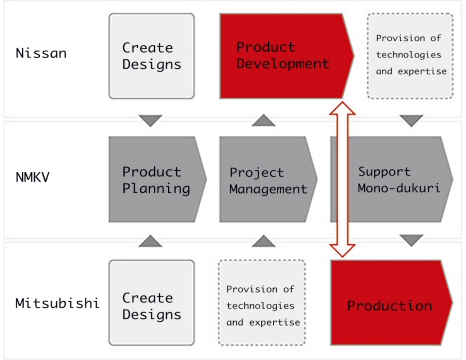

Kei-car holds an important segment in the market of Japan which accounts for almost 40% of the passenger vehicles. Aspiring to introduce the second-generation models to the market with enhanced potential, Nissan, Mitsubishi, and NMKV decided to take on a new challenge in October 2015. The existing structure of the product development facilitation and management run by NMKV will be strengthened and the development operations will be transferred to Nissan Technical Center (Atsugi City, Kanagawa) while the production role will remain the same and be the responsibility of Mizushima Plant of Mitsubishi – all of which meant to implement a new Scheme. The Kei-cars are to be developed by Nissan and manufactured by Mitsubishi. Easily described, but they were about to face many challenges in the days to come.

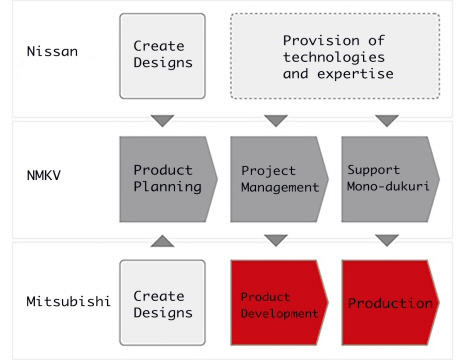

Old division of roles by the time of NMKV foundation

Division of roles after the implementation of new Scheme

The car-making process of the first-generation model works like Mitsubishi developing the models to proceed with the production with a partial adoption of Nissan’s expertise into Mitsubishi’s workflow. For the next second-generation models, it becomes necessary for the parties to establish and adopt a new Scheme by means of making adjustments and facilitating coordination between the car development process of Nissan and the car development/production process of Mitsubishi. They have their own unique set of processes in their workflow; most of them have different names, requirements, and execution periods. It requires a vast number of resources to be put in translation and interpretation and to reach an agreement in the unified terminology of such workflows. Saito CVE (Chief Vehicle Engineer) who is in charge of the product development and Nishiyama CPEO (Chief Production Engineering Officer) who is in charge of the production, recall that their job was “felt as if it was never ending”. The task to build a new Scheme was deemed extremely difficult, and it has only been made possible by the smooth communication of two companies with NMKV assuming the role as a hub. The quality communication is extoled by Horiuchi CTO (Chief Technology Officer) as “exceedingly even the level of cooperation among incremental product development and production department within a company”.

Junichi Endo, CEO

In October 2016, Mitsubishi joined a member of the Renault-Nissan Alliance. It was announced that they launch a variety of initiative programs to create synergies including but not limited to joint purchasing, shared manufacturing, and technology sharing.

“The second-generation Kei-cars made by NMKV will be the first project under the new alliance. NMKV is determined to make the most of the experience and expertise all three parties have accumulated so far, and to build a big success by the next models”,

Endo, President and CEO, spoke his enthusiasm.